|

|

|

||||||||

|

|

|||||||||

| Home | Forums | Register | Gallery | FAQ | Calendar |

| Retailers | Community | News/Info | International Retailers | IRC | Today's Posts |

|

|

|

Thread Tools |

|

|

#601 | |

|

Quote:

|

||

|

|

|

|

|

#602 | |

|

Quote:

The holes on the body(?) of that contraption allows air to flow BENEATH the rubber o-ring (but thot through the body. That would be useless). When this happens the o-ring will expand and create that so called "perfect" seal. The downfall of this set-up is that if that o-ring is not a very strong one, it will snap and break off. Alot of the NineBall DYNA piston heads have this issue.... Also, I didn't know that hi-capa/M9 and Glock piston heads were cross-compatible. I thought they had different sizes. The only cross compatible ones I knew of were the hi-capa/P226 ones. Interesting...

__________________

"May you fight with the strength of ten full grown men." Last edited by e-luder; February 10th, 2014 at 03:13.. |

||

|

|

|

|

|

#603 | |

|

Quote:

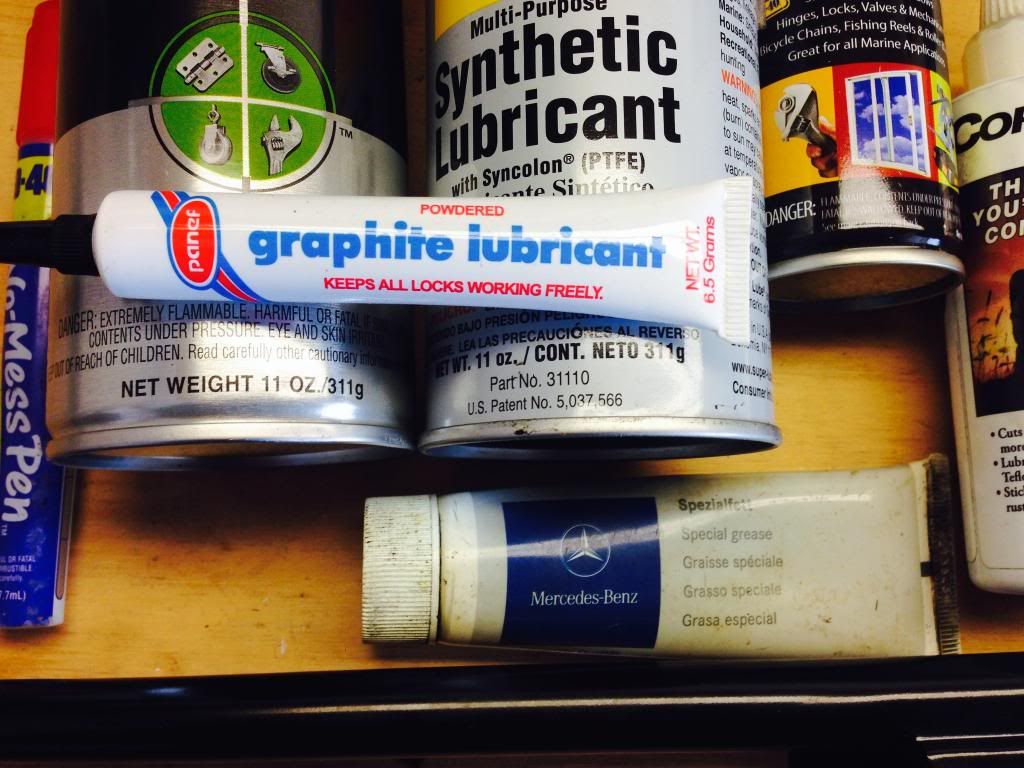

One last thing i would like to discuss: Graphite lubrication, well, lubrication in general. there are 3 basic and useful ways to lubricate, some of which i carry over from working on watches. (horology is the trade, to the layman it is "watchmaker") i digress..... so, lubrication #1: wet. as in, liquid, as in, silicone, 3 in 1 oil, superlube, and a million others i don't feel like typing. this is the most common, and often highly misused. it is however a simple concept: apply, let sit, wipe clean so nothing comes out during use. if done right, this can increase life and decrease wear of just about anything from RC Cars to watches, to real steel etc. Lubrication #2: DRY. as mentioned above, a fine graphite powder is often used to lubricate metals. it is fantastic, yet often misunderstood. this powder was designed (and is still marketed as a key hole lubricant (read: lock cylinder on your car door, home door, etc) and is meant to stay dry after application. its very nature is to have a static electric bond to moving and non moving metal parts of all grades, and therefore should remain in place once the excess has "fallen" off. after working in the industry for 2.5 yrs, this lubrication (the graphite, in case i'm losing anyone by being wordy) has really become popular and is very efficient. i must say that mixing it with an application agent (read: binder) and applying is counter intuitive however. this will cause it to become a paste as mentioned, and that is not its intended use. a polishing rouge would be better suited in this instance IMHO. Lubrication #3 wax-based: this is perhaps one of my favorites. its quite ingenious actually. originally designed for racing bicycle chains, this is a liquid that is applied, laid to rest, then cleaned off. the liquid leaves the surface (with COLD WATER and MILD hand soap) and what is left is a microscopic layer of WAX. yup, plain old WAX. (commonly used on, say, a Rolex metal bracelet to ensure smooth, squeak free movement of the links. i have used this for a million things, and i find it works wonders on polished, brushed, and bare metal to metal surfaces.) it also lasts a long time, and leaves no byproduct to release during use. they label it as "self cleaning" as well, although i don't see this in execution. Pictured below are just a few of the ingredients i use, i hope this is helpful to someone.....

__________________

My KSC G26 Build My "As close to real steel" TM/KJW G26 Build My "Anti-Snag/Smooth" TM/KJW G26 Build THE BEST 1911 PARTS ARE SOLD HERE Last edited by MikeMcNair; February 10th, 2014 at 11:13.. |

||

|

|

|

|

|

#604 | |

|

Ok, I'll begin my polishing process...but I can't understand is polishing the inner of the Outer barrel my be useful.

I want to polish every worn by contact parts; slide grooves, chassis, trigger bar. Is the Dremel red compund good for this? As soon I'll buy the graphite lubricant for the hammer parts. Quote:

|

||

|

|

|

|

|

#605 |

|

im sorry if i was unclear:

in the pic with the outer barrel in the drill; look closely, if you pulled the trigger the whole unit would spin, so you can polish the OUTSIDE of the barrel. the inside of the barrel is held by the dremmel sanding drum (think of it as a plug per se.) this was simply an example of using things around the house to get a job done quickly. (a makeshift lathe sotra :P ) if that still does not make sense, i will make a video. I do have a Q for E-Luder: Have you found a way to make the inner barrel NOT rattle against the outer barrel on these? In KSC/KWA world you can use O-Rings and it's a nice feature. i have yet to rid my current G26 of this last rattle, and it drives me nuts. thank you in advance for your thoughts. -Michael |

|

|

|

|

|

|

#606 | |

|

Quote:

It's hard for me to find o-rings that fit properly. ...and electrical is much more "modifiable" than an o-ring. That is, you can add or take away as much as you need. Whereas an o-ring doesn't share the same modularity. ...and and....It's cheap!!! (In every sense of the word.) That's what I normally do.

__________________

"May you fight with the strength of ten full grown men." |

||

|

|

|

|

|

#607 |

|

edited and posted a few posts down..........

__________________

My KSC G26 Build My "As close to real steel" TM/KJW G26 Build My "Anti-Snag/Smooth" TM/KJW G26 Build THE BEST 1911 PARTS ARE SOLD HERE Last edited by MikeMcNair; February 10th, 2014 at 20:03.. |

|

|

|

|

|

|

#608 |

|

Quote:

__________________

"May you fight with the strength of ten full grown men." |

|

|

|

|

|

|

#609 | |

|

Quote:

"polishing" and "filing/sanding" have different conotations. Although they undergo the same process essentially, they effects that you are trying to achieve is different. Polishing simply means (to me) smoothening out parts. Sanding/filing means REMOVING material to fit things into place. I was confused by what you were trying to achieve based on your wordings on the previous post but now I know. You don't really need to polish the inner side of the barrel. Mainly because you have an inner barrel for the barrel to ride along. I don't even think there are many people (if any at all) would polish their real steel barrel anyways. It will screw up the rifling inside. To me you shouldn't be using a dremmel at all. Other than using it for how MikeNair said to use it, it will not do you any favors. Good Old needle files and your own sweat and arthritis provoking hard work will get you a more precise result. A dremmel is ruthless on pot-metal. Plus it's very hard to control...

__________________

"May you fight with the strength of ten full grown men." |

||

|

|

|

|

|

#610 | |

|

Quote:

|

||

|

|

|

|

|

#611 |

|

I misinterpreted your pic, sorry

Im sorry if i was unclear: in the pic with the outer barrel in the drill; look closely, if you pulled the trigger the whole unit would spin, so you can polish the OUTSIDE of the barrel. the inside of the barrel is held by the dremmel sanding drum (think of it as a plug per se.) this was simply an example of using things around the house to get a job done quickly. (a makeshift lathe sotra :P ) if that still does not make sense, i will make a video. I do have a Q for E-Luder: Have you found a way to make the inner barrel NOT rattle against the outer barrel on these? In KSC/KWA world you can use O-Rings and it's a nice feature. i have yet to rid my current G26 of this last rattle, and it drives me nuts. thank you in advance for your thoughts. -Michael[/quote] Last edited by kar120c; February 10th, 2014 at 15:47.. |

|

|

|

|

|

|

#612 |

|

MikeMcNair,

may you suggest a solution for other issues I have with my KJW G27? I have 2 Kjw mags and 1 Marui mag. With KJW the pistol works well but the first shots cause gas vent from the back of the pistol. I tried to upgrade the rubber nozzles of the mag with the "purple" ones (I don't remember the brand) but is the first times all worked well but after a while the issue come back. Using the Marui mag I have striking failure if I insert the mag with the slide closed, but if I insert it with the slide opened all works perfeclty, no vent and mopre power than with kjw mags. I think something prevents the magazine to fit higher My set up is this KJW G27 OD green Guarder recoil and hammer springs Guarder steel recoil rod Guarder steel magazine catch Guarder front and rear sights Safety trigger (Kjw dosn't have it due to copyright issues) Guarder and Shooter design Valve knockers, but I can't get work none of them Last edited by kar120c; February 10th, 2014 at 16:15.. |

|

|

|

|

|

|

#613 |

|

can you post an image of the magazines lined up next to each other showing their "catch" points?

also, can you post an image of the mag catch removed from the frame please. i feel this is where your issue lies. E-Luder posted a "coke can" shim method in this thread somewhere (just search the thread). i personally have used each and every mag seal i could find, and frankly i HATED every one!!! the ONLY ones that have been consistent for me are the STOCK TM/KJW ones. i am unsure why. it sounds crazy, but they have been perfect for me, and NO OTHERS have worked more than a short time. please keep in mind, i have built all of my non KSC/KWA glocks from a combination of parts from TM and KJW, so i am very confident in their "interchangeability" with close regard to magazines, slides, BBH, trigger mech, etc. the fact that the gun shows issues when a mag is inserted with slide in battery, and no issue when slide is locked back, would also lead me to request pictures of the inside of the assembled slide. instinct says the nozzle is too far forward in battery, and perhaps the BBH is causing that. it is really hard to diagnose things without holding them in hand as i am sure you can imagine. how is the BBH seated in the slide? is it stable, solid, flat? does the BBH rattle around at ALL, or is the rear site holding it well? also, here is what i am looking for. in the following pics you will see 2 mag catch's, one is newer, one shows more wear. these were taken out of a KJW and a TM frame (i have both sitting RIGHT HERE). this is what i am looking for from you please. please note: the KJW mag is currently in my TM frame, and the mag baseplate from the KJ is on the TM as well. in other words, i have everything mixed up on purpose.

__________________

My KSC G26 Build My "As close to real steel" TM/KJW G26 Build My "Anti-Snag/Smooth" TM/KJW G26 Build THE BEST 1911 PARTS ARE SOLD HERE Last edited by MikeMcNair; February 10th, 2014 at 18:41.. |

|

|

|

|

|

|

#614 |

|

@kar120c with regard to your gun not firing when the magazine is inserted before the slide is cycled, leads me to think that it is possible that your new firing pin (knocker) is 'over sized'

I usually have this problem on my 1911's (just getting into a glock now)... but with new 'upgraded'/steel knockers they are frequently too large so they can be custom fit. The knocker - due to over sizing - may be getting caught on the magazine valve. That is why when you insert the magazine, the valve pushes up on the knocker and even when you cycle the slide there is too much upward pressure on the knocker to have it retract. Also could explain why it DOES shoot when you cycle the slide first (retracting the knocker) and then inserting the magazine since it will sit behind the knocker and not get caught on top as you insert the mag. The problem may also persist on TM mags and not KJW mags just due to their size difference... it could be as little as a few millimetres (clones arn't always perfect) |

|

|

|

|

|

|

#615 |

|

Apilar,

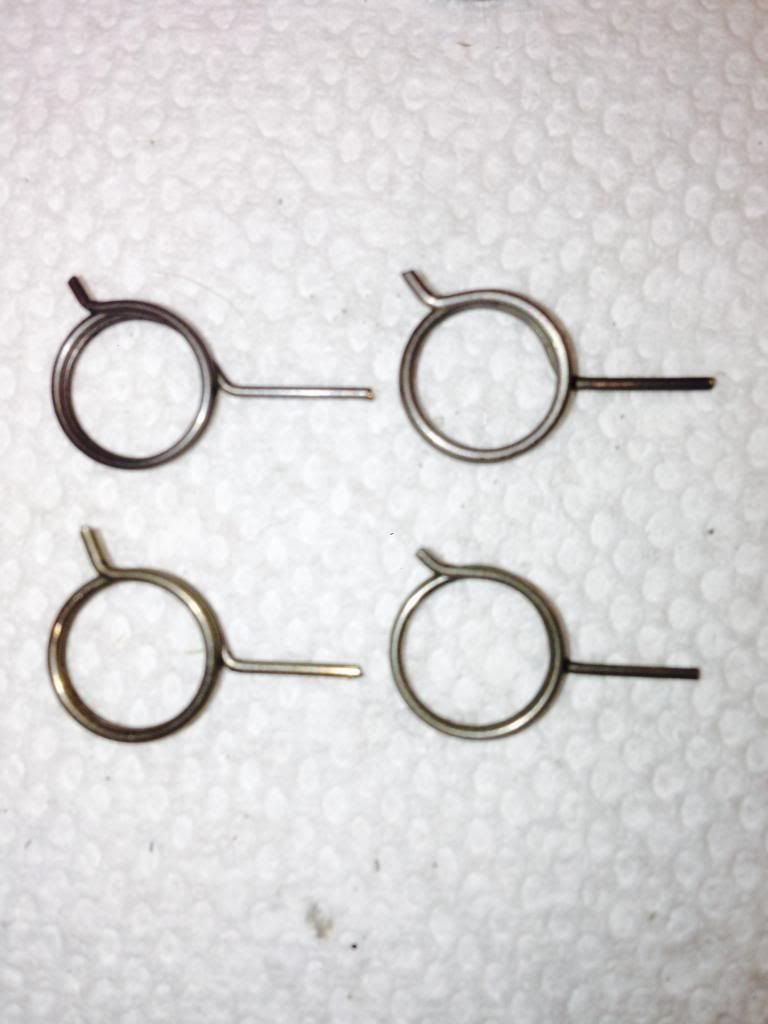

excellent point indeed! i must admit though, i have not run into a single issue with a single valve knocker one of these yet. i am in no way discounting the idea, simply sharing my experience. E-Luder & everyone: i posted this above, but fear it was missed, so i'm posting lower, down here lol... E-Luder: thank you! i was clearly over-thinking the innerbarrel/outerbarrel rattle. leave it to me.... now that i am thinking of questions you may be able to help with, i have a few more for you if you don't mind. 1) are you able to VISIBLY IDENTIFY the difference between a stock and (let's just say) a GUARDER recoil or hammer spring? i ask because i have about 6 or so springs that i am unsure of the manufacturer of. some examples are below. perhaps there is a test to see the tension? perhaps color or length (although almost all identical, i can see some SLIGHT variation, it could also be my aging eyes...) 2) have you ever found doubling up a recoil spring to be beneficial? this is simply out of curiosity. 3) have you ever fitted an aluminum BBH and consequent Piston Head from a G17 into the smaller G26 counterpart? this is something i have always pondered. i appreciate this thread, and your efforts tremendously! -Michael 2 photos with slightly different lighting to see if there is a discernible difference in these springs........

|

|

|

|

|

|

|

||||||

| Bookmarks |

| Thread Tools | |

|

|

|