|

|

|

#16 |

|

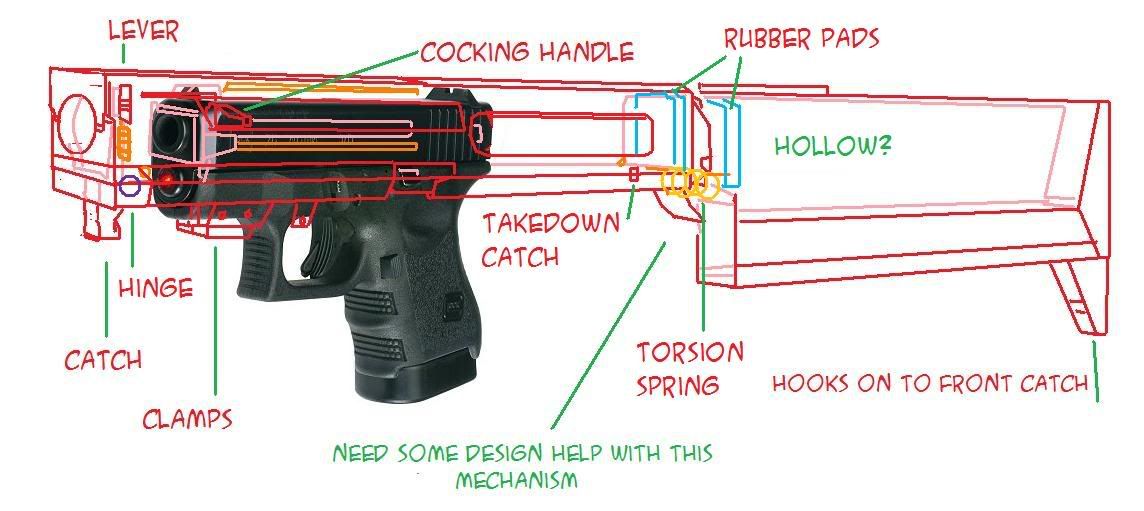

try this, and u can just make a little openning for the spring thats enclosed but close up everything else, would that work??

|

|

|

|

|

|

|

#17 | |

|

*AV Status Suspended pending trade resolution*

|

Quote:

That could work nicely, just gotta find something strong enough to hold it from both ends, and a locking mechanism (most likely identical to the front).

__________________

Age verifier- Halifax region |

|

|

|

|

|

|

#18 |

|

Schwag wannabe

|

Anyone have any suggestions for me? I'm going to be the one casting the mold and creating the chassis and all the little bits. I'm thinking of just going with polyurethane plastic, I made some spartan armour using that, it held up really well after sitting on it for hours at a time.

|

|

|

|

|

|

#19 |

|

i know i know, get a heavy spring and solder it to the frame of it, hopefully u get a heavy enough spring that wont break at the tip

also i would some how box the coil part caz u dont want it to turn on u, and mess every up, being that its under tension when not in use |

|

|

|

|

|

|

#20 | |

|

Schwag wannabe

|

Quote:

Also, I'm taking over for tonight/whenever Bob gets back so ask any questions you'd like, though I'd probably only be able to answer the ones related to the actual process of creating the shell and all the other bits. Also what would you guys think of using a central clamp to hold the glock in place instead of several smaller ones. http://img264.imageshack.us/my.php?i...owsthisbp1.jpg I think it'd be more stable that way. Last edited by Arthraxis; February 16th, 2008 at 03:08.. |

|

|

|

|

|

|

#21 |

|

*AV Status Suspended pending trade resolution*

|

Hmm- the central mag clamp could work, it'd just be far harder to make.

I'm at a friend's place right now and can't talk much, but here's a few things- I looked into the FMG again, and the actual design has a torsion spring installed almost exactly the same way Acer had it- so I think that's confirmed. The outer slide and frame will have to be thin, and a slot will have to be cut going through the back to accomodate blowback with the selector. It's no big deal, and is quite possible- also, a guide for the bolt would be nice. Any suggestions would be much, MUCH appreciated.

__________________

Age verifier- Halifax region |

|

|

|

|

|

#22 |

|

how exactly are u going to aim with it, caz if it going to be attached by the front rails on the gun, i dont think that will be sufficient of the weight of the glock or weight, caz that would seem like it will bend quite easily (being the weight it at teh back of the pistol, and attached to the front, leverage plays into this) this is what i recomend to reenforce it, u know that space between the mag, and the back of the grip how there is a space in there, somehow use that to attach to the frame, hopefully that makes sense

|

|

|

|

|

|

|

#23 | |

|

*AV Status Suspended pending trade resolution*

|

Quote:

I doubt it'd bend, there'd be two clamps- one in the front (quite tight), one at the trigger guard. If the means to get them are available, we can do one for the back- but it'll be tested thoroughly. Also, there won't be any iron sights AFAIK, simply a top-rail- I don't think the real-steel has iron sights, either. The back area should be reinforced with metal, with rubber pads on the end of the slide area and at the beginning of the stock, to dampen the blow. The parts that hold the torsion spring in should DEFINITELY be metal.

__________________

Age verifier- Halifax region |

|

|

|

|

|

|

#24 |

|

just another idea, i know its not like the original, but what if the top of the frame above the slide comes off, and u use the original sights,

|

|

|

|

|

|

|

#25 | |

|

*AV Status Suspended pending trade resolution*

|

Quote:

Here's stage 2 of the early design?

__________________

Age verifier- Halifax region |

|

|

|

|

|

|

#26 |

|

about it being off level to the stock and frame, just add a piece to lower the spring (on the frame side) too make it more centered

make sense, or need pic? |

|

|

|

|

|

|

#27 |

|

What are you doing for sights? A rail?

__________________

IN OMNIA PARATUS |

|

|

|

|

|

|

#28 |

|

*AV Status Suspended pending trade resolution*

|

Acer, I'm not sure what you'd mean, a pic'd be great.

And yeah, for sights, it'd simply be a rail- unless public opinion states otherwise.

__________________

Age verifier- Halifax region |

|

|

|

|

|

#29 |

|

being that the mag is longish the stock will have to be "tall', so put a piece metal (blue) to lower the spring, this way u can keep the top as flat as possible, make sense??

|

|

|

|

|

|

|

#30 |

|

*AV Status Suspended pending trade resolution*

|

That could work, I suppose- but the mag isn't really long at all, it has to be folded with a regular Glock 26 mag in it. It'll give you about 20 shots before you can slap in a 50-rounder and rock-out-with-your-Glock-out.

__________________

Age verifier- Halifax region |

|

|

|

|

|

||||||

| Bookmarks |

|

|

|