|

|

|

#16 |

|

Curious then. It was purchased by me with the understanding that it was a full systema mechbox, but I was always curious because I was under that impression that they did not make yellow pistons, and the only ones I had ever seen/worked with that were yellow were in CA boxes. Thanks for confirming my suspicion, Brian.

__________________

I love freedom and consequently America |

|

|

|

|

|

|

#17 |

|

GBB Whisperer

|

You would be surprised how many people don't actually know what's in their gun, nor do they really care. "As long as it works."

|

|

|

|

|

|

#18 |

|

Yeah true enough. Not me. Prefer to know exactly what I'm running so I can keep tabs on what experiences I've had with which companies and which products from those companies.

__________________

I love freedom and consequently America |

|

|

|

|

|

|

#19 |

|

If its a grainy mustard yellow colour its a CA piston. Its suppose to be CA's "better than stock" piston but have been known to fail as the quality is very hit and miss. I recommend changing it out for even a stock TM piston.

|

|

|

|

|

|

|

#20 |

|

I installed a Sorbo pad in a gun and the sound level dropped a lot, I then installed a MASK piston head as well and it got a whole lot louder, louder than it was before I installed the Sorbo pad. No idea why.

I have also never been able to use the white o-ring that comes with the MASK piston heads, I have to replace them with others I have in my parts bin to get any airseal at all. |

|

|

|

|

|

|

#21 | |

|

Quote:

|

||

|

|

|

|

|

#22 | |

|

Quote:

I have recently been doing some testing on sorbo products too and the result is that when combined, the MASK piston head and the sorbo pad do make a louder noise. -the airseal that the MASK piston head provides is terrible, it doesnt seal a single cylinder i have tried. Instead, if u have extra o-rings, that the only way to make it seal properly. However if u have time and patience, take light silicone lube and give it an oring bath in the silicone, it will expand the o-ring, but again...not suggested. - the sorbo pad itself (the blue one) does provide greater shock absorbtion than any stock black rubber. I have ran 2Xkwa mechboxes extensively at 450fps, one had a MAK kit and sorbo and the other one was full stock. The gearbox without sorbo pad and the MASK kit cracked the one with the sorbos is still running strong. |

||

|

|

|

|

|

#23 |

|

actually, the white o-ring is of inferior quality when compared to the black one. get the black replacement o-ring. it should fix all your ailments with your MASK piston head.

|

|

|

|

|

|

|

#24 |

|

Tys

|

Drifting off topic a bit...but worth commenting on.

The o-rings of many different piston heads do not seal well right out of the packaging...or right out of the box with several AEGs. There's not really a rhyme or reason to it...but I suspect that it's just a matter of having the o-ring exposed and sitting around in packaging for a while. I've also seen several "new", right out of the box AEGs that have had near to no lube on the piston o-ring or else the o-ring has "shrunk"...loosing most if not all airseal. On some, the grease was so crappy that it had pretty much solidified and gunked up so that there would never be a good piston head to cylinder air seal. I cannot suspect anything but that those AEGs were sitting around for a long time on a shelf as well. There's a couple of ways of getting a good piston head/cylinder airseal...and soaking an o-ring to expand it would not be one that I'd recommend. As said many times before on this forum...you can just chuck parts into a mechbox and expect the whole system to work well. It ain't rocket science, but there is some finesse to it. Urijo...your piston is a CA piston. I've only ever used two of them...both lasted 10K+ rounds before they were retired. One was retired because of wear...another was sacrificed on purpose for an exploding mechbox test (so it's not really fair to say that it failed...but it didn't survive). Lots of others have reported bad ones though...so it's probably hit or miss. Re. shaving the tooth...I'll take some pics next time I have it open (BTW, I reset the MOSFET and it works beautifully with the 11.1v LiPo again!)...but here's the jist of it. Counting teeth from the back end of the piston...do not do anything to the first tooth. With the mechbox open (and assuming that you have the MASK piston head and MASK cylinder head) push the piston all the way forward and hold it there. Carefully rotate the sector gear counter clockwise. You'll probably find that the first (leading) tooth of the sector gear will come around and either contact/engage/top-out on the second piston tooth. You'll need to remove enough material from that second piston tooth so that the first tooth of the sector gear clears the second piston tooth and continues on to properly engage the first piston tooth. Some people will only file off however much they need...some will remove the tooth entirely (I did). Add. note: Since the piston is now sitting back further the engagement angle of the leading surface of the first tooth of the sector gear and the surface of the first tooth of the piston are now different. Depending on the mold of both parts...the engagement surface may be acceptable or it may be quite bad. With a stock TM piston and the stock KWA gears...it was fine and I've now run 1000K through the setup with the MASK piston/cylinder head set, stock KWA M4 gears, TM piston and 11.1v LiPo. I'll tear it down after I field it at Op Broadsword this weekend. I'll try to take pics/vids at that time and if I have the chance, I'll swap in another piston/piston head combo and another piston/cylinder head combo for comparison. Back on topic...the MASK piston heads I received had a black o-ring that seemed pretty "fresh". I did re-lube it with a wipe of Lithium grease...but otherwise I didn't do any sizing to it. As stated...it did seal very well with the "stock" cylinders I had on hand. Tys Last edited by m102404; March 16th, 2009 at 23:51.. |

|

|

|

|

|

#25 |

|

Tys

|

Updated first post....

************************************************ Testing Platform Update: I was kicking around ideas of how to work through testing this stuff...and I decided to dive in and test a couple of other things at the same time. I wanted the test platform to be such that I could compare MASK vs. non-MASK setups in as similar as possible setups...without missing a mortgage payment. I'm going to test some of the new PP System pistons and their Torque Up gearset at the same time. It's supposed to be the same Prometheus items before they're branded Promethus....we'll see how they hold up. So I ordered the following just for these tests. 2 x PP System Hard Piston $25 2 x Modify Poly Bearing Piston $15 1 x Modify Air Seal Nozzle AK47 $9 2 x Modify Air Seal Nozzle M4 $9 1 x PP System Torque Up Gearset w/ Hard Piston $70 1 x G&P 7mm Complete Gearbox $210 + misc hopup rubbers and stuff. So after all is said and done...I should be able to comment a bit on: - PP Systems pistons...and compare to Modify pistons - PP Systems gear set...and compare to G&P gearset - ROF differences between stock JG, EG1000, Systema Magnum motors - Modify S90, S110, S120 and ASR 400/450 springs (not sure about how far I'll test each of these...) - MASK Piston Head vs. "Plain" polycarbonate piston head - MASK Cylinder head vs. "plain" piston head - more LiPo tests I will be testing the assemblies with just the mechbox and grip/motor attached...but I want to test primarily with it setup in an M4 shooting BBs...since that'll be how it's eventually used. I figured I'd retest all the Madbull BBs I got as well...still can't do controlled accuracy tests at range...but I should be able to get some consistency/comparative results. If anyone wants to chip in...ideally I'd get another G&P M120 mechbox to do a MASK/non-MASK test to destruction...but I'm tapped out at the moment. |

|

|

|

|

|

#26 |

|

Tys

|

Post Op - Check Up

Up until this weekend, I probably put more than 2K through this mechbox. While I kind of lost count...definitely the last 600 (probably closer to 1000) were with the MASK piston and cylinder head.

This past weekend I headed out to Op Broadsword and fielded the CQB M4 setup. They said it was supposed to be 2deg C...but it felt colder than that for most of the morning. It warmed up later in the day...but cold enough for a light jacket over long sleeves and Toronadoes and GBB's didn't work at all (well the Toronadoes did...but the timing was either 30sec or 9 minutes  ). ).I put 12-14 mid caps (120 rnds) through it (est. 1440-1680 rounds) . Mostly full auto (really most of the full auto was 3 rnd burst because of the mosfet setup). So definitely a brisk 2000 through it. I'll tear the rifle apart this week and see how it looks inside. Tys |

|

|

|

|

|

#27 |

|

m102404. I want to know how the PP Hard Piston hold on your test. I have 2 of this pistons which I am skeptical using them on clients Aeg. Cheers!

|

|

|

|

|

|

|

#28 |

|

Tys

|

Will do. Got to pick up the goodies early this week.

Tys |

|

|

|

|

|

#29 |

|

Bought the whole Sorbo set a few days ago, just arrived today. So after I finish this up I'll be installing it into my Mp5. Will write a comment in a few hours

__________________

|

|

|

|

|

|

|

#30 |

|

Tys

|

I'll pretty this up in a bit:

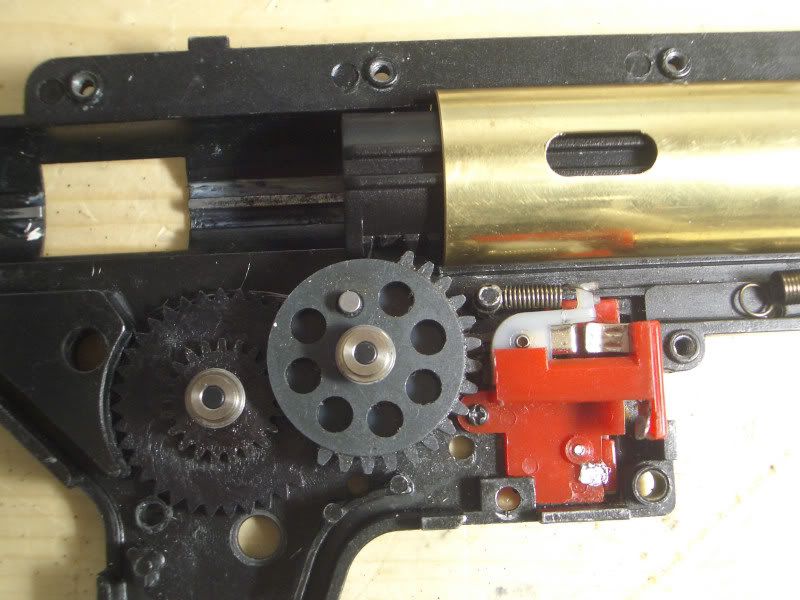

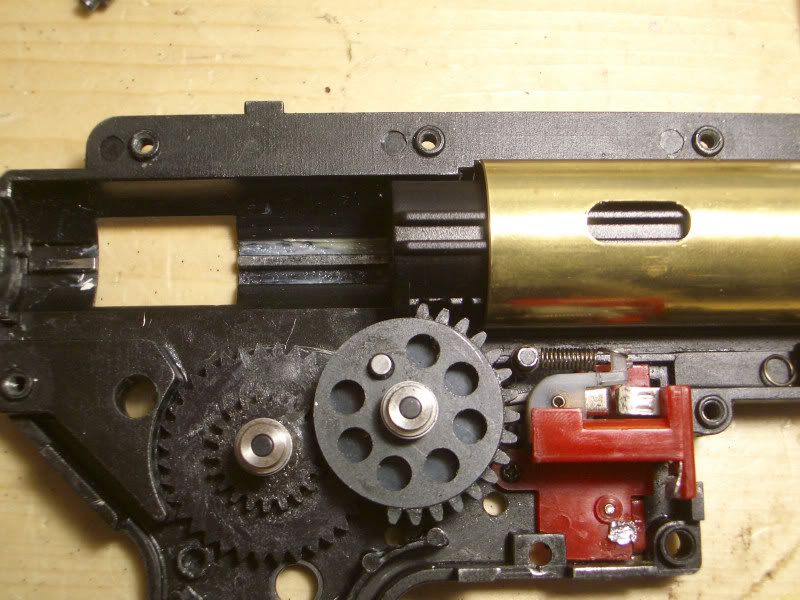

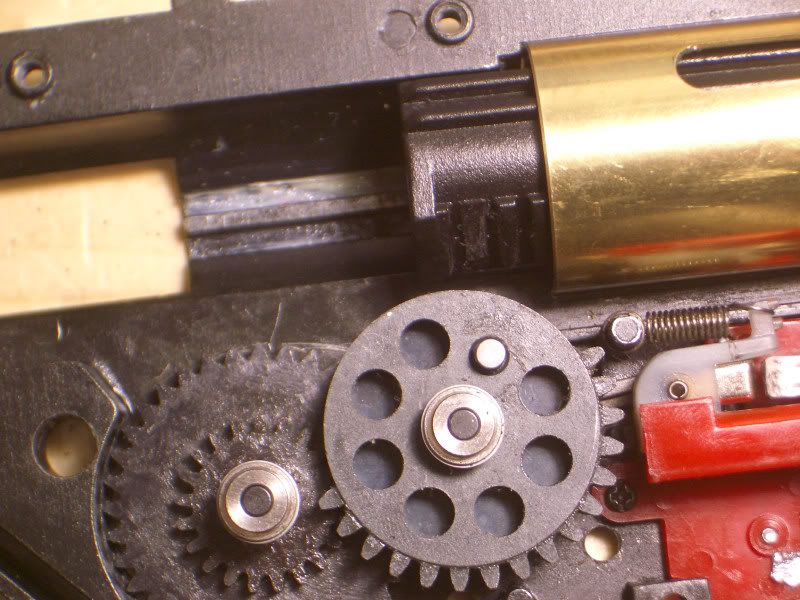

Testing Platform - Guarder Reinforced Mechbox - KA 6mm Dual Oil Channel SS Bushings - Modify V2 cutoff - KA switch w/ TM switch block - can't remember what gearset - Modify V2 bearing spring guide - misc M4 nozzle - junk tappet (replaced with a Modify V2 tappet - blue)  ASR MASK Metal Piston Head - extremely nicely machined - vents are counter sunk - o-ring was a very good fit - excellent seal with several cylinders right out of the packaging (mounted on PP piston) - sorbo tab seems secure - bearing stack, spacer and screw seem to install flush and square (i.e. not out of alingment)  PP Hard Piston - pre-Prometheus labled item. - plastic is extremely hard...seems fiberous almost when filing - similar to cutting or filing a white UHMW cutting board...same "slippery" feeling to it. - nicely molded, no sprue/flashing - full teeth, last 7 teeth are metal.  ASR MASK Cylinder Head - The piston head is extremely well machined. It sealed excellently with the three cylinders (various brass cylinders and one aluminum one that has worked very well in several builds). - A selection of M4 nozzles worked well with it...some leaked, others didn't, I just picked the one that worked best - Note how far out the sorbo padding and rubber mat protrude from the cylinder head.  Sector Gear Crashing - With the MASK Piston and Cylinder head installed and with the piston pushed forward, note how the first tooth of the sector gear contacts the 2nd tooth of the piston as it comes around. - I tried filing the 2nd tooth and quickly gave up and dremel'd it with a cutoff wheel (tough stuff). I orginally cut the 2nd tooth down by half...but it still wasn't enough, so I removed it completely (pretty much flush with piston body)  Still Crashing - upon closer inspection, the first tooth of the sector gear was just nipping the 3rd tooth of the piston as it came around...I slightly filed the back side of the 3rd tooth so that the sector gear would clear.  AOE - with the sector gear clear as it comes around to engage the first tooth of the piston...you can note the Angle Of Engagement as the two teeth make contact. - the contact surfaces were sufficiently flat on contact that shimming between the piston and piston head was not necessary.  2nd and 3rd tooth shaved - not a great pic, but you can see the removal of the 2nd tooth and shaving of the back of the 3rd (barely).  StickG Grease - I've been playing with this moly gear grease and silicone grease. I suspect the gear grease (black/grey) is molybendum disulphide...a common and well know lubricant. The grease is quite thin. I'm playing around with how much to use and how much of it stays on the gears after several 1000's of rounds. It's nice so far...but messy. - The silicone grease is quite thick, but can be spread on very thin. - nice little tub

|

|

|

|

|

|

||||||

| Bookmarks |

|

|

|