|

|

|

||||||||

|

|

|||||||||

| Home | Forums | Register | Gallery | FAQ | Calendar |

| Retailers | Community | News/Info | International Retailers | IRC | Today's Posts |

|

|

|

Thread Tools |

|

|

#781 | |

|

Quote:

__________________

|

||

|

|

|

|

|

#782 |

|

Tys

|

If the tip of the nozzle is getting stuck in the chamber you should alter either the rubber seal in the chamber or the tip of the nozzle such that there is little to no resistance when retracting the nozzle.

The o-rings of the nozzle that seal against the brass tube's chamber must be lubed. They get hit with a lot of gas and dry out quickly. The piston cup must also be lubed...since it'll drag against the brass tube cylinder portion if it's dry. The bolt carrier and nozzle assembly must travel freely and smoothly back and forth...if it's catching or binding then it'll obviously hang up the system. Basically gas will flow continuously until the hammer is cocked back to a given position. You can see/test this by manually cocking the hammer back with your thumb and watching where/when the knocker is kicked back into it's rearwardmost position. If the bolt carrier is not moving the hammer sufficiently...then gas will continue to flow until the mag is empty. If your lower is operating correctly...then the bolt carrier isn't retracting enough to set the hammer back. Could be: - poor gas seal between nozzle and chamber - poor gas seal between piston cup and cylinder - drag/friction/catching - excessive hammer spring tension - worn/broken parts between hammer (the little nub on it that trips part 66) or the arm of part 66 |

|

|

|

|

|

#783 |

|

Thanks for the reply Tyson! Much appreciated. Does Part #66 do anything on a WE M4? I know that when the hammer is cocked, it pushes up Part 66, allowing the firing pin to thrust forward when the hammer hits it. When the hammer is already in the forward position, Part 66 is permitted to be pushed down by the spring blocking the knocker from retracting. The thing is, the back plate of the valve knocker already prevents it the knocker from going backwards. So does Part 66 do nething except for facilitating the function that is already there? Im just thinking about what would happen if it is removed.

|

|

|

|

|

|

|

#784 | |

|

Tys

|

Quote:

Part#66 is critical to the functioning of the system. When the hammer goes forward it strikes the knocker...the knocker is spring loaded to snap back rearwards, but is held forward. You can observe that by cocking the hammer back just a bit and you'll see that the knocker stays forward (i.e. it would still be holding the knocker valve of the mag down...as gas would be flowing). If you were to take the trigger mech apart you would note a little bump on the hammer. This bump interfaces with the lower leg of Part #66. The bump bumps the leg and part #66 kicks the knocker out of position and it springs back (retracts back). When it does this...that effectively shuts off the gas from the mag. You can observe that by cocking the hammer back bit by bit until part#66 causes the knocker to flick back into it's reset position. I did miss in my previous e-mail that it is possible that a sharp corner of aftermarket Part#66's can wear out the nub on the hammer...causing things to fail. You can see if that nub is worn by taking the part #66 out of the trigger mech and by cocking the hammer while the trigger mech is out of the receiver. You should be able to look into the hole on the side and see the condition of the nub. A pre-emptive move would be to round the contact edge of aftermarket CNC'd part #66's...so that it doesn't wear the hammer. All it needs is enough of a bump to kick the knocker out of position. Compare a stock part #66 with some of the aftermarket CNC steel part#66 and note the rounded corner of the leg. Last edited by m102404; April 20th, 2011 at 16:41.. |

|

|

|

|

|

|

#785 | |

|

Quote:

So the other day I was just observing the function of Part 66, and watching how it moves as the hammer is cocked and this is what I observed. So the other day I was just observing the function of Part 66, and watching how it moves as the hammer is cocked and this is what I observed. When the hammer is pulled back, the nub on the hammer pushes the leg of Part 66, which causes this part to be pushed upwards. When this happens, the knocker is allowed to retract since it is spring loaded and uninhibited by Part 66. This effectively, cuts off the gas flow. Correct? Now lets take the same scenario but remove Part 66 from the equation. When the hammer is cocked, wouldnt the knocker still retract since it is spring loaded? Wouldnt its retraction still operate without Part 66? The reason why im asking all these questions is simply this: Sometimes when the hammer is cocked by the BCG, the knocker does not fully retract. I realized that I would have to cock down the hammer with greater force in order for the knocker to completely retract. After some observations, Part 66 is not being pushed high enough for the knocker to fully retract, that is why a greater force to depress/cock the hammer was required. A slight upwards push on Part 66 is all that is needed for the knocker to retract fully. However, I was just reading your description above: "When the hammer goes forward it strikes the knocker...the knocker is spring loaded to snap back rearwards, but is held forward. You can observe that by cocking the hammer back just a bit and you'll see that the knocker stays forward (i.e. it would still be holding the knocker valve of the mag down...as gas would be flowing)." and this may perhaps be normal. I was thinking about increasing the height of the nub on the hammer so that it can push Part 66 higher, allowing the knocker to retract more effectively. What do you think? Last edited by turok_t; April 20th, 2011 at 17:37.. |

||

|

|

|

|

|

#786 |

|

anyone think the we scar super bolt is a bad idea? I'm on the fence about getting it. YouTube - RA-TECH WE scar steel super bolt&TopM4 metal shell prototype Review.mpg

__________________

|

|

|

|

|

|

|

#787 | |

|

Quote:

Anyhow, what's this 'ihop system' that he speaks of? Obviously a hop up, but any specs on it? It also looks like it's only marginally capable of firing all BBs in the mag before running out of gas (first mag of auto fire)... I'll be awaiting reviews for sure. With all that, one would imagine they'd just start selling their own all upgraded open bolt kit with bolt carrier, slide, #66, #27, hop up, inner barrel, and npas. Maybe an all steel trigger box to go along with it (that hammer roller pin is a notable weak point). That would be a killer kit. I'd call it "Awesomify your WE SCAR". Although there wouldn't be a whole lot of WE left. |

||

|

|

|

|

|

#788 | |

|

Quote:

__________________

|

||

|

|

|

|

|

#789 |

|

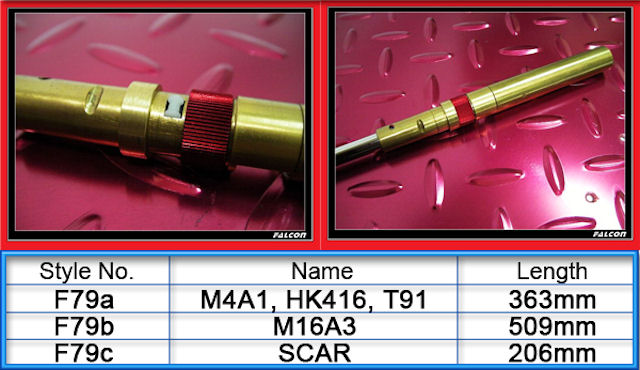

I received my Falcon Double Point Hop-Up today...I did a quick swap out after work today and I extremely happy with the early results.

I was using a RA-Tech inner barrel with a Stinger Hop-Up. Right off the bat my range has increased with no hooking. Plus the hop actually works on this!!! More testing is required. Included is a redesigned front section of the brass tube, a redesigned hop-up rubber and nub, and a redesigned barrel. Here's a picture of the system

|

|

|

|

|

|

|

#790 |

|

Tys

|

Sweet Barry...now, group buy!

The guys are going to Renegade)'s place on Sat for a tech/range session in prep for 24...check in with Coach/Wildcard/Renegade)/etc...if you want to join in. Tys |

|

|

|

|

|

#791 |

|

That's a shame that system is gonna be obsolete in a few months...

|

|

|

|

|

|

|

#792 |

|

Lol Tys!!!

I have 4 of these units inbound (don't ask why  ). I'll give you one to play with if you want ). I'll give you one to play with if you want  Shoot me a PM if you want to try one out. I should have the other three by this weekend. I wish I could make it out on Saturday but I got work...it would a perfect venue for some field testing. |

|

|

|

|

|

|

#793 |

|

8=======D

|

I believe you are mistaken

__________________

Brian McIlmoyle TTAC3 Director CAPS Range Officer Toronto Downtown Age Verifier OPERATION WOODSMAN If the tongue could cut as the sword does, the dead would be infinite |

|

|

|

|

|

#794 |

|

Just a question for you guys.

My nozzle rod, or whatever it's called keeps on wiggling itself loose through firing, should I juse use some temporary locktite on it to keep it in place? or is there something else I should use? Thanks! (WE scar, btw) |

|

|

|

|

|

|

#795 |

|

|

|

|

|

||||||

| Bookmarks |

|

|

|