|

|

|

||||||||

|

|

|||||||||

| Home | Forums | Register | Gallery | FAQ | Calendar |

| Retailers | Community | News/Info | International Retailers | IRC | Today's Posts |

|

|

|

Thread Tools |

|

|

#1 |

|

Well L96 Bolt Handle troubles..

Dang thing. Wasnt sure if i should post this in the newbie tank or not..

Anyways. Pop the mag in, bolt handle up, pull it back, push it forward, try to push it down, wont go down. Thing is if i take the mag out (dont want to double feed bbs in it) and cycle the bolt back and forward a bit, it then sometimes goes down when i push it down. I have only just recently started to have this problem. Also sometimes it works very smooth like it normally should. I have been noticing that the bolt handle/end is getting the tiniest bit loose from the cylinder. Not sure if that could be the problem and if i should tighten it onto the cylinder? (googled, couldnt really find anything on specifically this problem). thanks in advance. |

|

|

|

|

|

|

#2 |

|

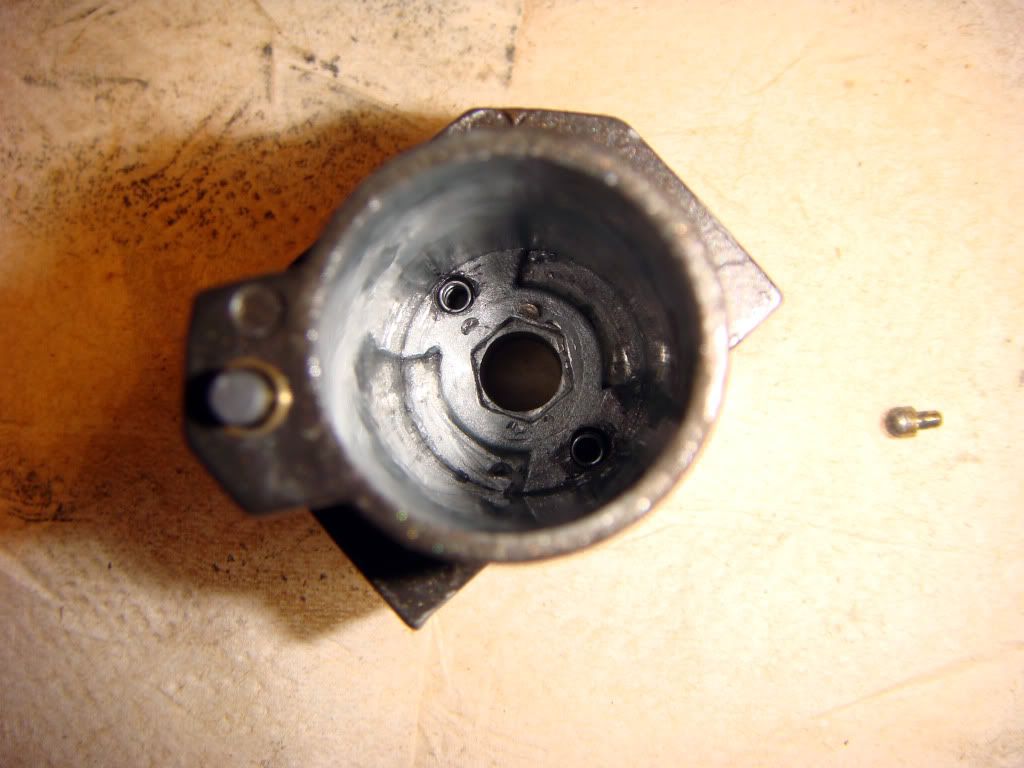

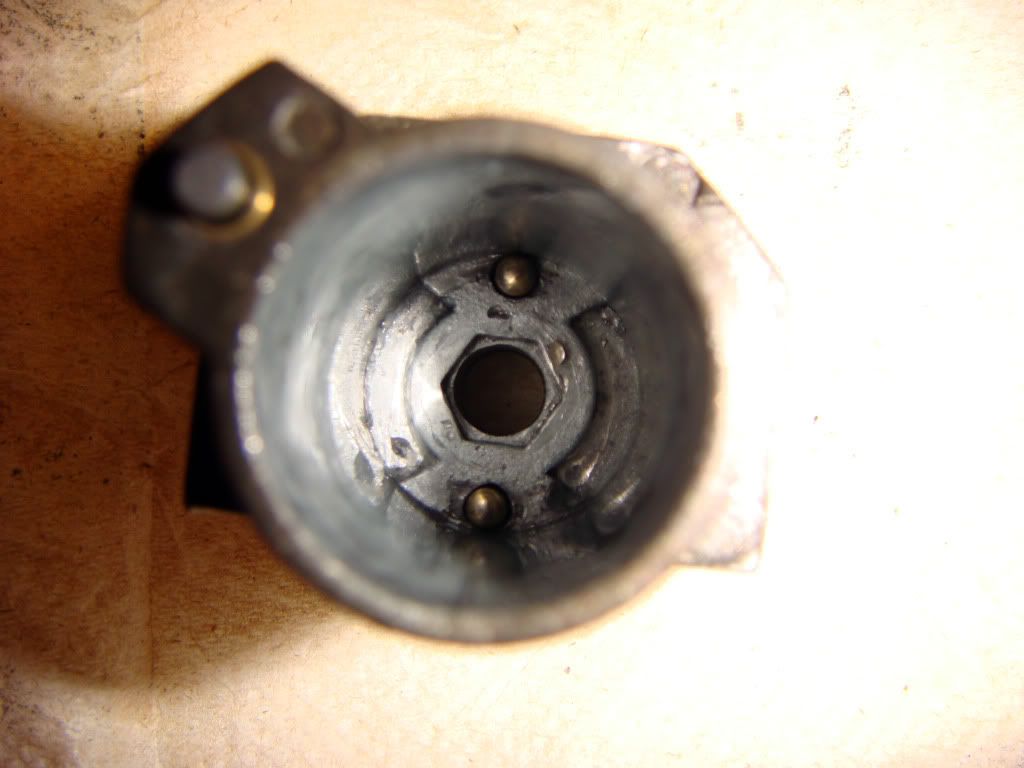

The bolt assembly has 2 pins that sits on springs and the bolt handle that inserts into the bolt assembly has corresponding dents that line up with the pins (the pins keep the bolt in the up or down position). There are 2 common problems that I've noticed with my Well L96 bolt:

1) The bolt assembly and handle are made from crap metal and deforms very easily where the pins are a harder brass-like material. If the dents have been deformed, the pins no longer line up properly and the bolt gets stuck. 2) Also, as you mentioned, if the bolt handle starts to get loose, sometimes the pins will fall out of the hole and get stuck between the bolt handle and assembly. If you move the bolt when this happens, you'll cause problem 1. Open up the bolt assembly and check to see that everything's fine. If it's all damaged, the only thing you can do is order a new one. I believe that Guarder makes one. edit: When I have time, I'll take pictures of mine to show you what I mean.

__________________

Last edited by aznpos531; June 10th, 2010 at 00:25.. |

|

|

|

|

|

|

#3 |

|

Alright. Thanks Very much. Yeah, pictures would probably be a helper as well.

|

|

|

|

|

|

|

#4 |

|

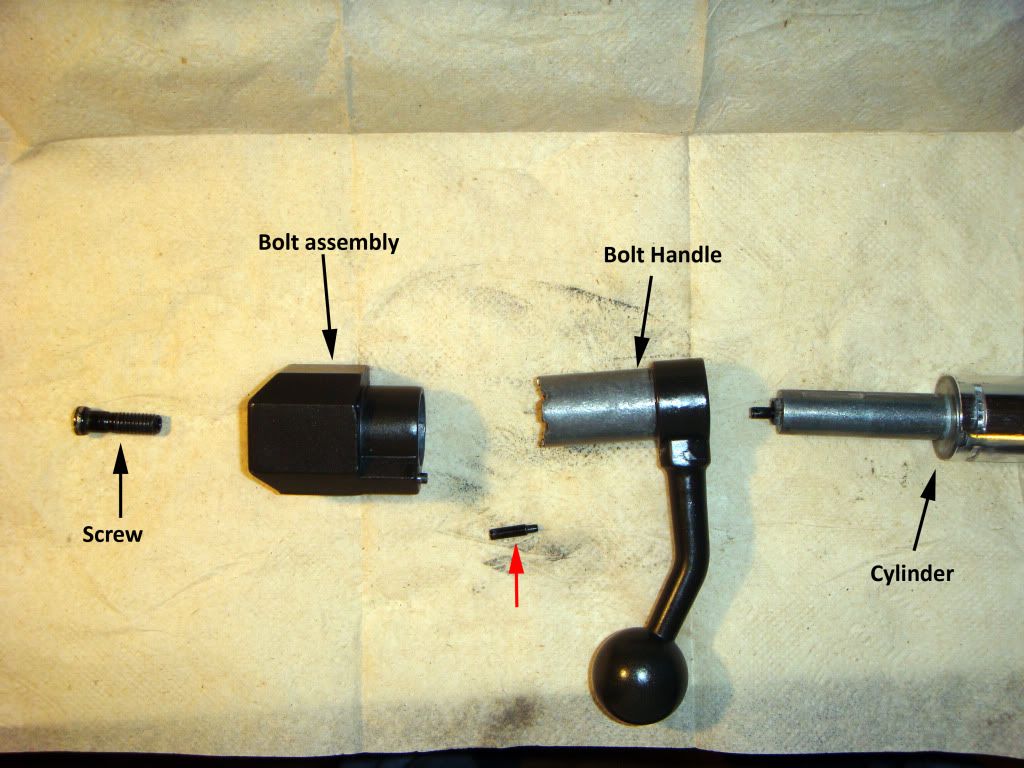

So here we have the disassembled bolt. Take note of the pin marked with the red arrow. It goes in the bolt handle, skinny side towards the cylinder (as shown in the second pic). To reduce play between the handle and cylinder, just tight the screw at the leftmost of the first pic.

This is the entire bolt assembly and handle. Note the skinny side of the pin poking out of the handle.  This shows them taken apart. Note the damage I mentioned in the previous post marked with the black arrow. The damaged area is where the pin (shown later) goes into the dent. Also, note the protrusions and dents marked in blue. This allows the bolt handle to rotate within that arc.   These little suckers are the pins.  To give you an idea of size, here they are next to a dime.  Here is the bolt assembly with the pins removed, springs exposed.  You will need tweezers or long nose pliers to seat them into the holes like so.  Hope this helps. If you have any other questions, just post back. One thing I will mention, when putting the bolt handle and bolt assembly together, make sure the pins don't fall out of place or you will end up doing damage to either part.

__________________

Last edited by aznpos531; December 24th, 2010 at 02:51.. |

|

|

|

|

|

|

#5 |

|

Thanks very much! Very helpful and i will most definitely go and try to fix this. Pictures helped a lot! Dam little finicky pins..

Edit: YES! finally! IT was the far left screw that needed tightening! Thank you very much for your help. Ill keep this knowledge with me. =] Last edited by Blitzed; June 10th, 2010 at 19:18.. |

|

|

|

|

|

|

#6 | |

|

Quote:

|

||

|

|

|

|

|

||||||

| Bookmarks |

|

|

|