|

|

|

||||||||

|

|

|||||||||

| Home | Forums | Register | Gallery | FAQ | Calendar |

| Retailers | Community | News/Info | International Retailers | IRC | Today's Posts |

|

|

|

Thread Tools |

|

|

#1 |

|

P90 cutoff lever or switch issue..

Ok, my TM P90 has the usual problem of firing full auto when in semi mode. The cutoff lever is brand new, but the gun is also new to me and I'm not completely sure how it all works yet.

Can someone explain to me how the thing is supposed to work? I know there's a cam on a gear that moves the lever up, but I can't figure out how that is supposed to break the electric circuit and stop the gun. From what I can tell, the lever doesn't touch anything where it sticks into the switch housing. I can't figure out from looking at it how it is SUPPOSED to work, so maybe someone can help me out. Thanks in advance. Last edited by XZIVR; May 1st, 2011 at 00:05.. |

|

|

|

|

|

|

#2 |

|

Ok, did some more testing and I tried an old 7.2v nimh battery I had laying around. Semi worked just fine with that. It's just a 7.4v or 11.1v lipo that causes the problem.

I can't really figure out why this would be though. Any ideas? All I can come up with is maybe the return spring on the cutoff lever isn't strong enough and it's causing the lever to 'float' when the gears are moving that fast. Same idea as valve float on a car engine if anyone knows what that is. With this new info, I would appreciate it if a mod could change the thread title.. |

|

|

|

|

|

|

#3 |

|

What is inside your gun motor and gears and spring? Very likely that your motor is just cycling and turning the gears quick enough that the cut off cannot properly engage the cam on the sector gear.

Very common problem if the gun is mostly stock and you are pllugging in LiPo batteries. Possible short or arcing. but very unlikely. Solution: Trigger master, slow down the motor with the settings Stiffer spring, Lower power motor, High torque gears can get you varying degree's of success with achieving reliable semi. |

|

|

|

|

|

|

#4 |

|

That's more or less what I was trying to say when I was talking about it floating. It's got upgraded internals though. Piston, torque gears, etc.

|

|

|

|

|

|

|

#5 |

|

Check and make sure the spring that acts upon the cut off lever is their. and tighten the screw that holds the lever to the gearbox. If it's an upgraded gun what gear ratio/motor are you using?

I have awful problems with my guns cycling too fast for my taste. WIthout the trigger master my gun shoots 2-3 round bursts on semi with the lipo and auto is 1800RPM+ @ 420FPS. I solved it by using a trigger master. I had the same problem with my CQB gearbox (Bone stock) but I solved that by running 7.4 lipo instead of the 11.1v that I prefer to use and being sure to firmly & fully pull the trigger, and shimming the cut off lever a little higher to better engage the sector nub. |

|

|

|

|

|

|

#6 |

|

Yup, screw's tight, spring's there. How does a triggermaster work with a p90 trigger setup anyway? And how would it help? Just slowing down the motor?

|

|

|

|

|

|

|

#7 |

|

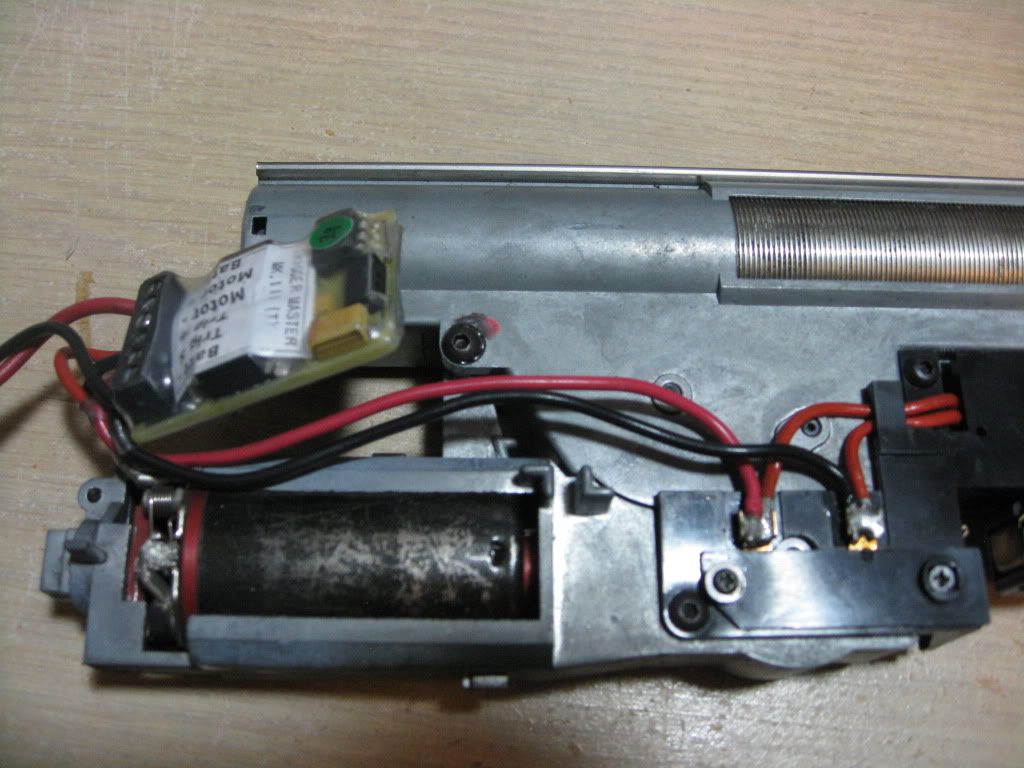

I used the TM to slow down the motor 70%. The way the unit works is that you get full power to the motor on the first shot and after the cycle is complete the TM reduces power to the motor on subsequent shots thus reducing ROF. Their is no loss of trigger response. I believe that feature was implemented version 3.7+.

The Trigger master on a P90 is literally 10,000x easier to work with than any other gun on the market as the switch is external to the gearbox. Here is a shot of the wiring harness on my field gearbox. Pictured is a custom trigger master unit. It was the very first 3.6, 3.7, 3.8, and 3.9 board produced. However a standard version will still fit nicely into the space between the spring guide and the motor. DonP has told me not to worry about strong magnets in the motor interfering with the operation of the TM unit. The TM unit is able to lean proper semi function, and uses active braking to stop the motor and prevent the gun from over cycling (shooting more than once, and it's suppose to stop the sector gear at the same place with each shot on semi).   PS.. Forgot to mention, you may want to contact Gandolf on ASM or Mike (can't recall his ASM handle). They make the extreme-fire units, and I can't remember other one. These 3 people collaborated and created the trigger master. Don did all of the software, Terry did the hardware, and Mike did the board layout. The hardware, components and layout of each make is identical (Trigger master, extremefire etc) what is different is the software. Don is amazing at coding. I believe that Don now is out of the trigger master business and requests for new units should be directed to Mike or Terry. They can burn Don's software onto the CPU.

__________________

Do you know what ruins airsoft? (Chair), (Drama), (Air), (Sugar) softers, filthy casuals --- --- WANTED PTW Receiver PRIME, STG, Factory Last edited by Azathoth; May 1st, 2011 at 03:21.. |

|

|

|

|

|

|

#8 |

|

Hmm, interesting. What I was asking though, was how does it know semi auto from full auto? How does it know when the gearbox has made one cycle? Cant seem to find that anywhere. The guy I bought the gun from was going to give me one of these and then ended up giving me different wiring all together.. Maybe I should see if I can still get it..

|

|

|

|

|

|

|

#9 |

|

Just bought a cheetah-2n from Terry. Good guy. I'm still figuring out the programming part :P.

Another thing the new one has is some "smart speed" thing, where the first shot is at the maximum motor speed, it slows down the shots after, so you won't lose response time, and can still have a slower rate of fire. |

|

|

|

|

|

|

#10 | ||

|

Quote:

Quote:

|

|||

|

|

|

|

|

#11 |

|

Try different sectors gears. The operation of the cut off lever is dependent on the sector gear, since there is a notch there the moves it. This notch is probably worn out.

__________________

It is the mark of an educated mind to be able to entertain a thought without accepting it - Aristotle -Founder of Steel City Hamilton Infantry and Tactics -Certified level 43 Autosniper by Commander Amos |

|

|

|

|

|

|

#12 |

|

You know what, I just had a look at my friend's F2000 which has a similar setup, and I noticed that the cutoff lever on his takes a whole lot less force to release the semi auto contact and make it pop out. What would cause mine to be so tight? Should I grease it?

|

|

|

|

|

|

|

#13 |

|

You know that screw you checked for tightness... untight it and recheck.

Also put a piece of electrical tape on the outside switch and try again. The outside switch is the F/A switch. It will prevent the gun from firing more than one shot in any mode. If it works, then it's the metal arm inside your gun that is too bent back. Bend it again and try. It is hard to get the right spot but it is possible. |

|

|

|

|

|

|

#14 |

|

I actually already tried the eleectrical tape thing, and the problem persisted. As for the cutoff lever screw, I have the gearbox in front of me right now with the trigger assembly removed, and the lever moves freely. When I use a screwdriver to try and pop the semi auto blade up, it still takes a lot of force.

On an unrelated (or not?) note, the thing now seems to be firing very weakly once in a while.. Sometimes the bb's will just dribble out the barrel, sometimes they will actually bounce back off my cardboard target, and sometimes they fire just fine. WTF? |

|

|

|

|

|

|

#15 |

|

Ok, so what's happening now is it's double feeding most of the time. The air nozzle isnt ending in the same position after each shot (no matter what battery I use) so it's double feeding a lot. I suspect maybe this stems from the cutoff lever issue?

|

|

|

|

|

|

|

||||||

| Bookmarks |

|

|

|